Company Presentation

WAREHOUSE RACKING MARKET SIZE, SHARE & TRENDS ANALYSIS REPORT BY PRODUCT

WAREHOUSE RACKING MARKET SIZE, SHARE & TRENDS ANALYSIS REPORT BY PRODUCT

REPORT OVERVIEW

The global warehouse racking market size was valued at USD 8.2 billion in 2018 and is expected to grow at a compound annual growth rate (CAGR) of 3.6% from 2019 to 2025. Increasing demand for capacity expansion in warehouses and storage facilities is likely to drive the market for warehouse racking systems over the forecast period. Increasing demand and the need for systematic storage and easy material handling are anticipated to support industry growth.

Increasing awareness regarding optimumutilization of spaces across supply channels, such as distribution centers, storage utilities, and stockyards, is likely to aid the industry growth. Racking offers cost-effective and systematic storage operations for heavy and fragile objects. Moreover, the long lifespan of the metal rack framework is anticipated to increase its popularity over the forecast period.

In the U.S., a selective pallet racking system emerged as the major product category in 2018. A well-established distribution network and growing online retail industry in the country have contributed to the growth of the warehouse industry, thereby influencing the market on a positive note. Furthermore, the acceptance of modern automated equipment in storage systems has encouraged the demand for drive-in racking systems in the country.

Racking systems are primarily manufactured using structural steel and other metals such as iron and aluminum. Technical innovations by manufacturers to introduce a rigid rack framework, pallets, and attachment products have enhanced the life of warehouse racks. The aforementioned factors are likely to drive product demand in heavy end applications such as industrial machinery and automotive.

These systems are considered cost-effective and efficient warehouse management techniques. Pallets used in structures can carry heavy loads. These systems are easy to maintain and can be easily relocated and restructured according to warehouse dimensions.

Shifting consumer preferences from traditional shelving to racking structures to utilize and enhance existing storage facilities are anticipated to aid the market. These racking systems can be installed according to warehouse space availability and desired storage form. Moreover, the ability to restructure racks according to the dimensions of an object is likely to propel their demand.

Product Insights

In 2018, selective pallet racking system emerged as the largest product category. It offers easy replacement of damaged components and adjustments of metal beams for different heights and pallet accommodation. Simple design structure coupled with provision for easy handling of objects in this racking type has supported its demand.

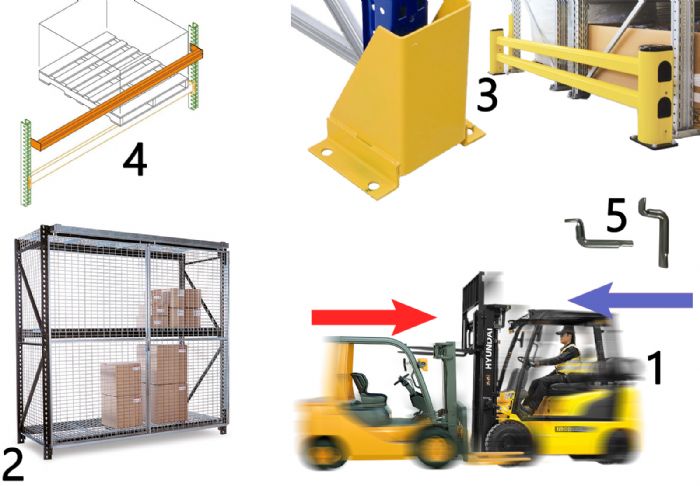

Drive-in racking systems are gaining popularity as these products offer easy access to objects. Forklifts and hydraulic machines allow easy accessibility of objects in between the racks. However, high cost associated with the installation of these racks is likely to hinder their market growth.

Picture 1- Drive In Rack systems occupy little space and have got high loading capacity. In this way, space of warehouse is efficiently used.

Cantilever racking systems are majorly used in large warehouses to accommodate long size objects such as pipes, rods, panels, structural sheets, and frames. These racks are catching consumer attention as they can accommodate products on both sides and can be easily accessed by machinery and forklifts. Growing demand for metal rods, pipes, and panels in construction industry is likely to have a positive impact on market growth.

Şekil.2-In addition to carrying long products such as sheet metal and pipe, cantilever rack systems can also carry pallet loadings thanks to sturdy steel plates that were placed on the cantilever arms.

The demand for pallet flow racking system in Europe was valued at USD 115.5 million in 2018 and is anticipated to progress at a CAGR of 2.2% from 2019 to 2025. Easy handling without imposing high load while carrying and displacing stored objects offered by these systems is expected to aid their demand. However, the movement of pallets in this racking system disables tracking the desired object, which is likely to hamper their demand over the projected period.

Picture 3 - Pallet flow system is the system which was based on gravity and it easily provides the flowing and storing palleted products.

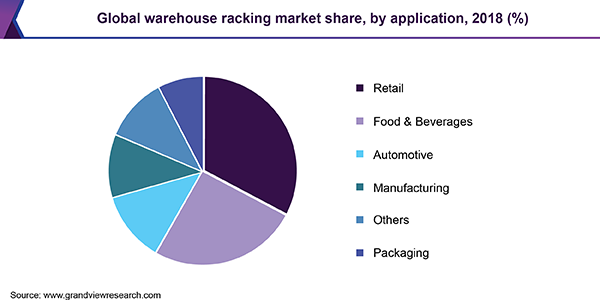

Application Insights

In 2018, retail application accounted for the largest share for the consumption of racking systems and is anticipated to ascend at a CAGR of 5.2% over the forecast period. Growing retailing sub-segments, such as online retail, hypermarkets, supermarkets, convenience stores, and food retail, are further likely to support industry growth. The expansion of multinational retail companies in the developing regions is further anticipated to support the market.

Picture 4 - A view from the warehouse of Amazon which was the greatest retail online giant in the world.

Automotive application accounted for a significant share in 2018 owing to the need for large and durable racking systems to store heavy and fragile objects. Growing automotive industry across the globe has created a scope for construction of new warehouses. Growing demand for automotive aftermarket components is likely to contribute to the expansion of warehouses, thereby influencing the industry on a positive note.

In 2018, food & beverages application accounted for the second-largest share in the global market. Increasing consumption of packaged and processed food products in the major regions including Asia Pacific and North America is expected to support the industry growth over the forecast period. The rapid growth of the retail industry on account of increasing urbanization, rising disposable, and changing consumer dietary habits is expected to drive demand for warehouses, thereby impacting the market positively.

Manufacturing industry across the major regions is experiencing rapid growth on account of increasing industrialization. To optimize distribution networks of manufactured products, industry players are focusing on the establishment of distribution centers, which is anticipated to aid the market for warehouse racking. Optimization of supply channel and transportation & storage costs is likely to propel the demand for warehouse racking.

Regional Insights

North America dominated the global market for warehouse racking in 2018. Well-established distribution network, early adoption of racking systems, and continuous innovations for storage space optimization have resulted in high demand for racking structures in the region. Growing retail and food industries in the region are the major contributors to the construction of new warehouses, which in turn, is likely to propel product demand.

The U.S. emerged as a key consumer for racking systems on account of well- established industrial sector in the country. Wide range of racking systems is used in warehouses to ease material handling process. Moreover, early acceptance of automated technologies in storage facilities has introduced forklifts and hydraulics that has positively impacted the market in the country.

The demand for selective pallet racking system in Europe is anticipated to progress at a CAGR of 3.6% over the forecast period. Increasing construction activities of new warehouses and distribution centers across the U.K., Germany, and Spain are likely to support the market. Furthermore, the region is an automotive production hub with the presence of major manufacturers. Thus, automotive industry is expected to be a major consumer for warehouse racking in the region.

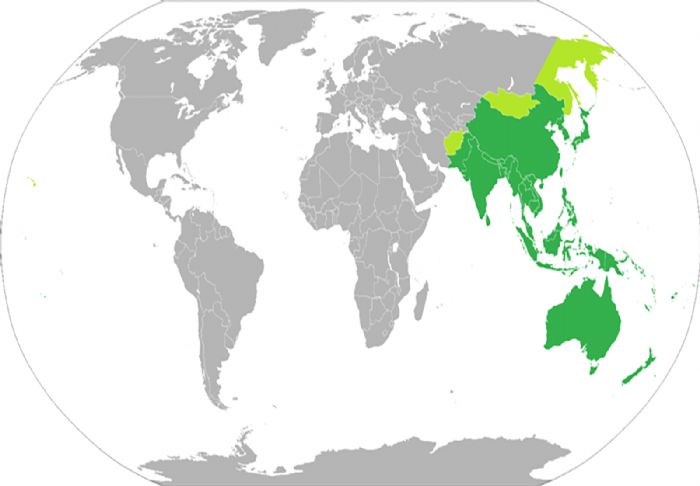

In Asia Pacific, food & beverage and retail industries are anticipated to account for significant consumption of racking systems over the forecast period. Rapid population growth in China and India, which demands high volumes of packaged food products, is expected to drive the retail industry in these countries, thereby impacting the warehouse racking market positively.

Key Companies & Market Share Insights

Prominent players in the market include Daifuku Co., Ltd., Mecalux, S.A., Kardex Group, Hannibal Industries, EMRACK INTERNATIONAL, and Jungheinrich AG. These players compete based on material quality, designs, and pricing structures. Moreover, players are focusing on introduction of racking components with enhanced durability and high load-bearing capacity to sustain in the competitive market.

Key players are also targeting to enhance their portfolios by providing design and installation services for warehouse racks. Daifuku Co., Ltd. designs various storage, material handling, and sorting solution systems for manufacturing, distribution, and airport management systems. Also, it offers automated technologies for racking systems, wherein, materials can be handled efficiently. Some of the prominent players in the warehouse racking market include:

-

Daifuku Co., Ltd.

-

Mecalux, S.A.

-

Kardex Group

-

Hannibal Industries

-

EMRACK INTERNATIONAL

-

Jungheinrich AG

Segments Covered in the Report

This report forecasts revenue growth at global, regional & country levels and provides an analysis on the industry trends in each of the sub-segments from 2014 to 2025. For the purpose of this study, Grand View Research has segmented the global warehouse racking market report on the basis of product, application, and region:

-

Product Outlook (Revenue, USD Million, 2014 - 2025)

-

Selective Pallet

-

Drive-In

-

Push Back

-

Pallet Flow

-

Cantilever

-

Others

-

-

Application Outlook (Revenue, USD Million, 2014 - 2025)

-

Automotive

-

Food & Beverage

-

Retail

-

Packaging

-

Manufacturing

-

Others

-

-

Regional Outlook (Revenue, USD Million, 2014 - 2025)

-

North America

-

The U.S.

-

Canada

-

Mexico

-

-

Europe

-

The U.K.

-

Germany

-

Spain

-

Italy

-

Russia

-

-

Asia Pacific

-

China

-

Japan

-

India

-

-

Central & South America (CSA)

-

Brazil

-

-

Middle East & Africa (MEA)

-

Saudi Arabia

-

-

WAREHOUSE RACKING MARKET SIZE, SHARE & TRENDS ANALYSIS REPORT BY PRODUCT ...

WAREHOUSE RACKING MARKET SIZE, SHARE & TRENDS ANALYSIS REPORT BY PRODUCT

CLICK FOR DETAILS

HOW SMART SHELF TECHNOLOGY WILL CHANGE YOUR SUPERMARKET ...

You may want to start paying attention to supermarket shelves because they are changing rapidly. Soon, when you walk by a shelf filled with prod

CLICK FOR DETAILS

METALSYSTEM AT THE SERVICE OF ITS USERS! ...

&

CLICK FOR DETAILS

SET RAF IS FASTLY MOVING UP IN EXPORT ...

SETRAF Accelerates in Exports Offering qualified solutions in the field of Supermarket, Storage Rack Systems and Equipment, SET RAF has been exporting to more than 40 countries. SET RAF has been providing quality solutio

CLICK FOR DETAILS

MARKET SEGMENTATION IN HEAVY DUTY RACKS IN THE WORLD ...

"Increasing demand for industrial racking systems in multiple sectors, such as logistics and e-Commerce" The increasing number of warehouses across the globe is the primary facto

CLICK FOR DETAILS

THIRD PARTY COMPANIES IN LOGISTICS AND RISING GIANT IN INDUSTRIAL RACK MARKET : ASIA PASIFIC ...

First of all, it is useful to understandGlobal Market Study on Industrial Racking Systems: Rapid Advancement of Third-party Logistics Augmenting Market Growth

CLICK FOR DETAILS

FREE DISCOVERY POSSIBILITY ...

Free discovery possibility... We offer free exploration opportunity at Set Raf. We produce the best projects for you. Why? With an effective planned project, we analyze all your needs

CLICK FOR DETAILS

SET RAF 2019 CATALOGUE WAS PUBLISHED AND E-CATALOGUE WAS POSTED. ...

CLICK FOR DETAILS

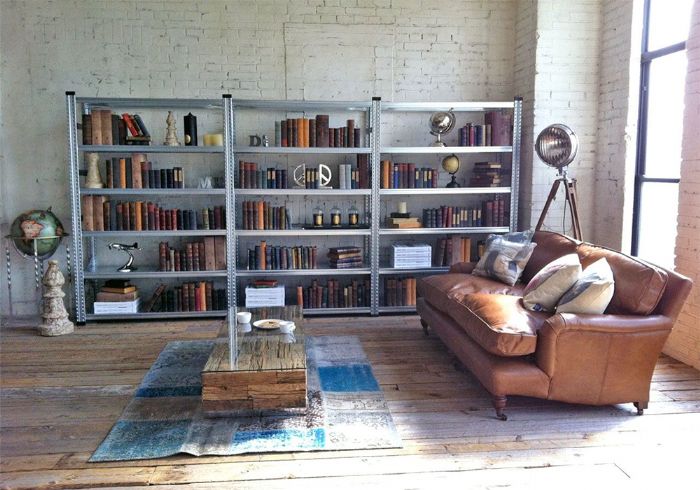

METALSISTEM SUPER 1-2-3 PRODUCTS ARE IN OUR STOCKS ! ...

METALSISTEM SUPER 1-2-3 which descreased the cost and provided more storage area, is galvanization interpenetrated rack system is manufactured via highest technology in Euro Norms.With the wide lin

CLICK FOR DETAILS

SET RAF IS WITH YOU IN ITS SHOWROOM. ...

CLICK FOR DETAILS

SECURITY IN HEAVY DUTY RACKS ...

Heavyduty racks are the structures what contained significant load as both size and heaviness in their own constituiton. They are also indispensable elements of warehouses.They have got critical roles about healthy storing

CLICK FOR DETAILS

THE RACK SYSTEMS WHICH WILL BE PREFERRED IN HEAVY DUTY STORAGE ...

Before the World War II, pallet rack systems were not common .The becoming actual way of pallet rack systems again, offered warehouses to ability of t

CLICK FOR DETAILS

5 BASIC PRODUCTS THAT MAKE UP A SUPERMARKET ...

5 BASIC PRODUCTS THAT MAKE UP A SUPERMARKET Wall units can be installed in any desired area thanks to production a

CLICK FOR DETAILS

JAM SUPERMARKETS CHAIN PREFERED THE SET RAF PRODUCTS. ...

One of our important export customers to whom we supply supermarket shelves, Jam Supermarkets chain continues its activities rapidly in its region. While Jam Supermarket continues to inc

CLICK FOR DETAILS

SET RAF IS PUTTING THE PRODUCTS OF METALSISTEM WHICH WAS MARKET LEADER IN THE WORLD , INTO THE S ...

One of the main reasons for the success of our products; METALSISTEM’S shelving and racking systems series are made from prime quality, high tensile, certified, hot dipped zinc coated steel. This proce

CLICK FOR DETAILS

OUR NEW WEBSITE IS ONLINE ...

You can benefit our website for reaching the detailed information about us.

CLICK FOR DETAILS

WAREHOUSE RACK SYSTEM ...

WE HAVE SUCCESFULLY COMPLETED OUR HEAVY DUTY SYSTEM PROJECT. PALLET RACKING SYSTEM

FOLLOW US ...

So that you can follow us more closely ... Follow Us Closer We took our place in all channels that are widely used in order to follow us more closely. By following us on Social Media, you can b

CLICK FOR DETAILS

The big hypermarket chain that we have been serving for a long time has again chosen Set Raf in the ...

The big hypermarket chain that we have been serving for a long time has again chosen Set Raf in the shelves of the last store it opened at the end of 2018. We have provided the installation to the supermarket project in

CLICK FOR DETAILS

WHO CAN USE OUR PRODUCTS? ...

Who can use our products? We answer this question under the visual scheme

CLICK FOR DETAILS

ALL THE DETAILS ABOUT HIGH QUALITY GALVANIZATION STEEL RACK SYSTEMS WHAT YOU CAN USE IN THE CLOSE ...

The dimensions of four shelved product which we presented your usage is 200 x 90 x 40 (as centimeter) , it's only one shelf loading capacity is 180 k

CLICK FOR DETAILS

SHUTTLE RACK SYSTEMS ...

In cooperation with Setraf & Metalsistem & Cassioli…

CLICK FOR DETAILS

INDUSTRIAL AND HARDWARE SHELF SYSTEM ...

When it was planned according to it's aim, it provides maximum efficency for your business via most convenient budget. Principle what we have&n

CLICK FOR DETAILS

MARKET RACK SYSTEMS

MARKET RACK SYSTEMS

METALSISTEM

METALSISTEM

MARKET EQUIPMENTS

MARKET EQUIPMENTS

STORE SHELF SYSTEMS

STORE SHELF SYSTEMS

WAREHOUSE RACK SYSTEMS

WAREHOUSE RACK SYSTEMS

CABINET SYSTEMS

CABINET SYSTEMS